Resonac and PulseForge Unite to Advance Photonic Debonding for Next-Gen Semiconductor Packaging

This agreement with Resonac is a major step in our mission to advance semiconductor manufacturing.”

AUSTIN, TX, UNITED STATES, June 26, 2025 /EINPresswire.com/ -- Resonac Corporation and PulseForge, Inc. are pleased to announce a strategic partnership to advance and promote photonic debonding technology for next-generation semiconductor packaging as of April, 2025. This collaboration aims to drive the adoption of photonic debonding into high-volume manufacturing, offering a high-throughput, low-stress, and industry’s best cost-effective solution for temporary bonding and debonding of ultra-thin wafers.— Jonathan Gibson, CEO of PulseForge

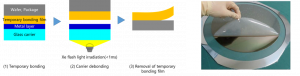

In the front-end and back-end processes of advanced semiconductors, wafers and chips are temporarily bonded to a glass carrier with a temporary bonding material to improve workability. After various fabrication processing, the wafers or packages are debonded from the carrier along with the temporary bonding material. Therefore, the performance of the temporary bonding material must be compatible with all fabrication processes, and the residual temporary bonding material must be easily removed.

The advantages of Resonac and PulseForge’s technologies are critical to advanced packaging applications, including 2.5D/3D heterogeneous integration, wafer-level packaging (WLP), chiplets, and high-bandwidth memory (HBM).

Photonic debonding leverages PulseForge’s proprietary high-intensity pulsed light systems and light-absorbing glass carriers to enable clean, low-stress separation of device wafers from temporary carriers. Unlike laser debonding, this approach significantly reduces wafer stress, improves yield, and lowers the overall cost of ownership.

Resonac’s specially engineered temporary bonding film is optimized for the photonic debonding process. Designed to support device wafers as thin as 20 µm and suppress surface undulation during chip bonding. The film enables clean, easy-peel of the film post carrier separation while minimizing downstream cleaning efforts, offering customers a streamlined and robust packaging workflow.

Resonac has fundamental method patents with respect to the photonic debonding process covering this collaboration and PulseForge holds an exclusive license for the light source products and debonding equipment using such light source products under such Resonac’s method patents, solidifying its unique position in enabling this next-generation process.

“This partnership represents a shared vision to push the boundaries of what's possible in advanced packaging,” said Hidenori Abe, Executive Officer at Resonac. “We see photonic debonding as a breakthrough process that aligns with next-generation requirements in both logic and memory applications.”

“This agreement with Resonac is a major step in our mission to advance semiconductor manufacturing,” said Jonathan Gibson, Chief Executive Officer at PulseForge. “Resonac’s leadership in material innovation and their strong ecosystem relationships make them an ideal partner to demonstrate the performance, reliability, and cost-of-ownership benefits of photonic debonding.”

As part of the agreement, Resonac and PulseForge will conduct joint customer engagements and co-marketing efforts across Asia, North America, and Europe. The companies will work collaboratively to optimize process integration, ensure materials compatibility, and support global adoption of photonic debonding at scale.

About Resonac Corporation

Resonac Corporation is a functional chemical company established as a result of the integration of Showa Denko and former Hitachi Chemical in January 2023 and a world-class leader particularly in semiconductor materials for packaging process. As a “co-creative chemical company,” Resonac aims to continue growing and enhance its corporate value through co-creation. We will accelerate technological innovation through co-creation with semiconductor, material, and equipment manufacturers around the world.

Official Website https://www.resonac.com

About PulseForge, Inc.

PulseForge, Inc. develops and manufactures state-of-the-art flashlamp-based tools that deliver energy in a precise and targeted manner to enable innovation in industrial manufacturing. Our expertise and tools empower our customers to explore novel materials and manufacturing methodologies, driving dynamic and efficient production at an industrial scale.

Contacts

Resonac Holdings Corporation

Media Relations Group, Brand Communication Department

Email: pr_med@resonac.com

PulseForge, Inc.

Vikram Shreeshail Turkani

Director, Technology Partnerships and Strategic Business Development

Email: vikram.turkani@pulseforge.com

Phone: +1 269-743-8168

Vikram Turkani

PulseForge, Inc.

+1 269-743-8168

vikram.turkani@pulseforge.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.